3d Filament guide

3d Filament guide

Welcome to our comprehensive guide to 3D printer filament! This guide is designed to help both beginners and experienced users learn more about the different types of filament available for 3D printers. We will go through the most popular filaments such as PLA, ABS, PETG and TPU, as well as their advantages, disadvantages and best uses. Whether you are printing prototypes, functional parts or artistic projects, here you will find all the information you need to make the right choice of filament.

As an introduction in our 3D filament guide is PLA Filament, or Polylactic Acid, one of the most common and user-friendly materials for 3D printing. PLA filament has good prices that can be obtained even better as a 3D printer refill and of course also easy to use. Its eco-friendly properties come from renewable sources such as corn and sugarcane making it a popular choice when it comes to 3D printer. PLA filament is also available in many different colors, giving you extra options for your printing projects.

Extruder

190-210 °C

Building plate

45-70 °C

Cooling

100 %

Benefits

Cost effective

PLA is often cheaper compared to other filaments due to its popularity and ease of availability.

easy to use

Due to the properties of the material, PLA is one of the easiest filaments to print with.

Environmentally friendly

Made from renewable resources, making it biodegradable.

Disadvantages

Skirt

PLA is more prone to breaking under load compared to other materials.

Low heat resistance

Deforms at relatively low temperatures.

Absorbs moisture

May affect print quality if not stored properly.

3d filament comparison

| Property | PLA | PLA+ | PLA PRO |

|---|---|---|---|

| Material | Polylactic acid | Modified polylactic acid | Fortified polylactic acid |

| Strength | ● ○ ○ | ● ● ○ | ● ● ● |

| Flexibility | Brittle | Slightly flexible | Rigid |

| Printability | ● ● ● | ● ● ● | ● ● ○ |

| Surface finish | Standard | Improved | Smooth |

| Layer stapling | ● ○ ○ | ● ● ○ | ● ● ● |

| Temperature resistance | ● ○ ○ | ● ● ○ | ● ● ● |

| Applications | Basic prototypes, Low-load models | Prototypes, Functional parts | Prototypes, Functional parts, Mechanical components |

*In relation to each other

Extruder

220-250 °C

Building plate

95-110 °C

Cooling

0-100 %

Benefits

Heat resistant

Moderate Stiffness

Durable and good impact resistance

Disadvantages

Tends to shrink during printing

Can be difficult to use in some cases

Gives off a bad smell when printing

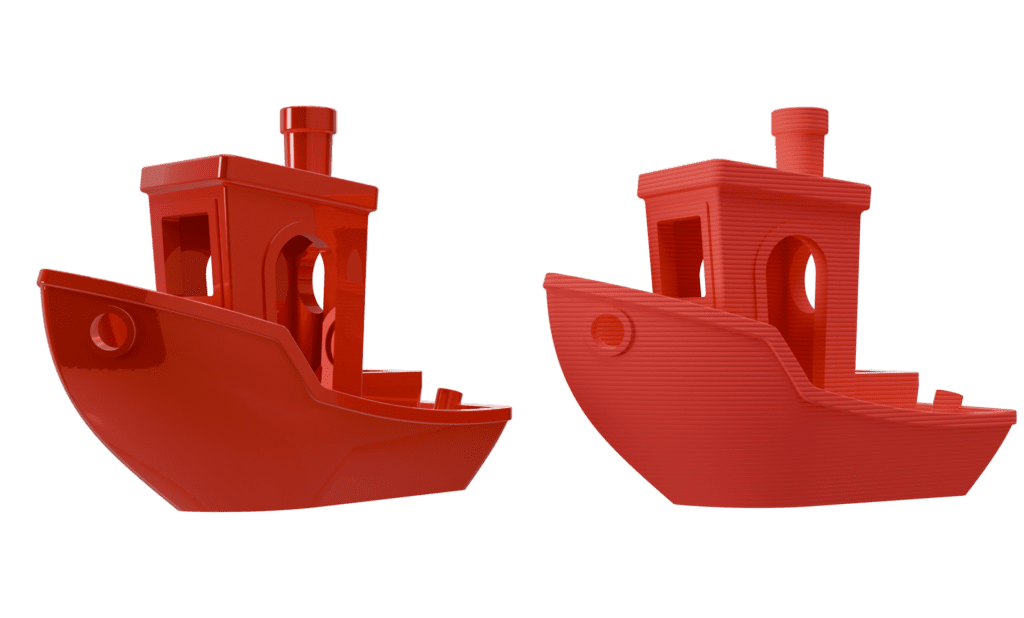

Acetone treatment

Using acetone to smooth 3D prints is a method that is mainly effective on ABS plastic, not on all types of filament. Follow these steps to use acetone and achieve a smoother surface on your ABS prints:

1. Prepare printout

Acetone works best on ABS plastic. Make sure your 3D print is made of ABS filament before using acetone

2. Create a closed environment

Place the 3D printed model in a container or a sealed bag. This helps create an environment where the fumes from the acetone can act on the surface of the print.

3. Apply

Moisten a sponge, a piece of torn cloth or a cotton swab with acetone. Then place the moistened surface in the hold with your 3D print. Alternatively, you can use an acetone vapor chamber.

4. Ventilate properly:

After the process is complete, air out your 3D print properly to remove any remaining fumes from the acetone.

3d filament comparison

| Property | ABS | PLA |

|---|---|---|

| Material composition | Acrylonitrile butadiene styrene | Polylactic acid |

| Strength | ● ● ● | ● ○ ○ |

| Flexibility | Less flexible | More flexible |

| Printability | ● ○ ○ | ● ● ● |

| Layer stapling | ● ● ○ | ● ● ● |

| Temperature resistance | ● ● ● | ○ ○ ○ |

| Applications | Mechanical parts, Industrial prototypes | Consumer products, Prototypes |

*In relation to each other

In our filament guide we will now talk about Polyethylene terephthalate glycol, or PETG filament which is a thermoplastic polymer. A 3D printer filament that has become popular and versatile thermoplastic due to its ability to combine the advantages of both PLA (polylactide) and ABS (acrylonitrile butadiene styrene). PETG is known for its high strength, good adhesion, and its ability to resist moisture and UV light, making it a reliable material for various applications.

Extruder

230-250 °C

Building plate

75-90 °C

Cooling

100 %

Benefits

Chemical Resistance

High UV resistance (Good outdoors)

Good prices on various colors

Disadvantages

Perceptible For Stringing

Poor Overhang Ability

3d filament comparison

| Property | PET | PETG |

|---|---|---|

| Material composition | Polyethylene terephthalate | Polyethylene terephthalate glycol |

| Strength | ● ● ○ | ● ● ● |

| Flexibility | Rigid | Moderately flexible |

| Printability | ● ● ○ | ● ● ○ |

| Surface finish | Smooth | Smooth |

| Layer stapling | ● ● ○ | ● ● ● |

| Temperature resistance | ● ● ○ | ● ● ● |

| Applications | Prototypes, Packaging | Prototypes, Functional parts, Mechanical components |

*In relation to each other

ASA is a UV resistant thermoplastic 3D filament, similar to ABS but with improved weather resistance. It is particularly suitable for outdoor applications and retains its mechanical properties over time when exposed to the sun's UV radiation. We have chosen to include ASA in our 3D printing filament guide due to its popularity and versatile uses. A must try material if you ask us.

Extruder

220-245 °C

Building plate

90-110 °C

Cooling

0-100 %

Benefits

High UV Resistance

High glass temperature

High impact and wear resistance

Disadvantages

Relatively expensive

High printing temperature

Bad smell and steam during printing

3d filament comparison

| Feature | ASA | PETG |

|---|---|---|

| Material composition | Acrylonitrile Styrene Acrylate | Polyethylene terephthalate Glycol |

| Strength | ● ● ● | ● ● ● |

| Flexibility | Somewhat flexible | Some flexibility |

| Printability | ● ● ○ | ● ● ● |

| Surface finish | Smooth | Smooth |

| Layer stapling | ● ● ○ | ● ● ○ |

| Temperature resistance | ● ● ● | ● ● ○ |

| Applications | Outdoor applications, Auto parts | Outdoor applications, Mechanical parts |

*In relation to each other

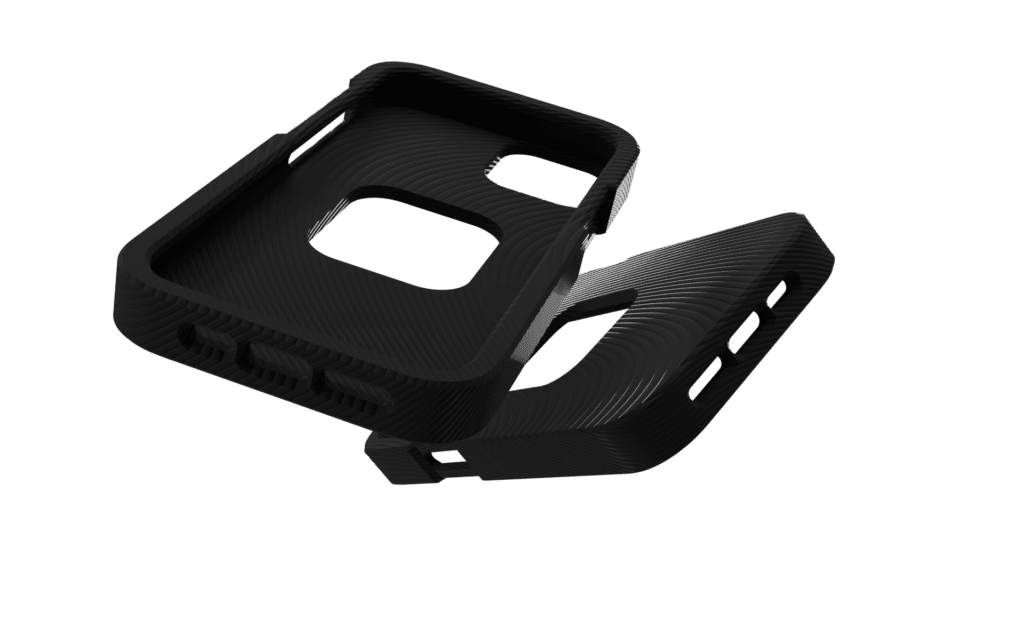

Next up in our 3D filament guide is TPU filament, or thermoplastic polyurethane filament. It is a type of 3D filament used to create flexible and elastic objects. TPU is made from a type of thermoplastic rubber and offers properties such as high elasticity, resistance to oils and moisture, as well as good wear resistance. TPU filament is popular for creating flexible details such as phone cases, shoe soles, and other products where flexibility and durability are important.

Extruder

190-210 °C

Building plate

45-70 °C

Cooling

100 %

Benefits

Many new uses

Elastic and Soft

Strong Bonding Ability

Disadvantages

Difficult Printing

Bad Overhangs

May need to be dried before use

3d filament comparison

| Property | TPU | PLA |

|---|---|---|

| Material composition | Thermoplastic polyurethane | Polylactic acid |

| Strength | ● ● ○ | ● ○ ○ |

| Flexibility | Flexible | A bit flexible |

| Printability | ● ● ● | ● ● ● |

| Surface finish | Improved | Standard |

| Layer attachment | ● ● ○ | ● ● ○ |

| Temperature resistance | ● ● ○ | ● ○ ○ |

| Applications | Prototypes, Low Load Components | Simple Prototypes, Low Load Models |

*In relation to each other

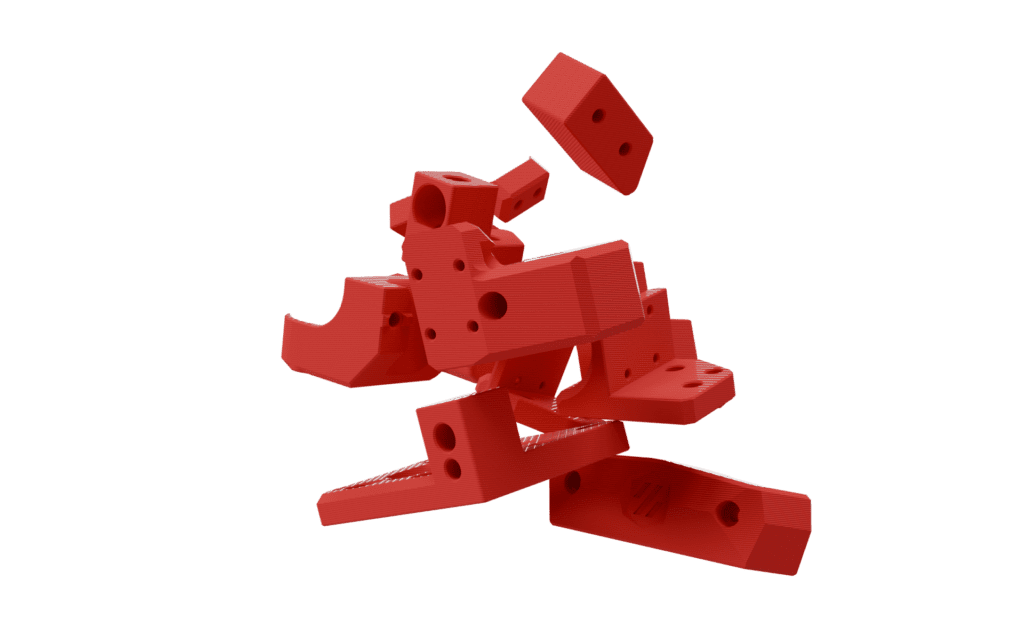

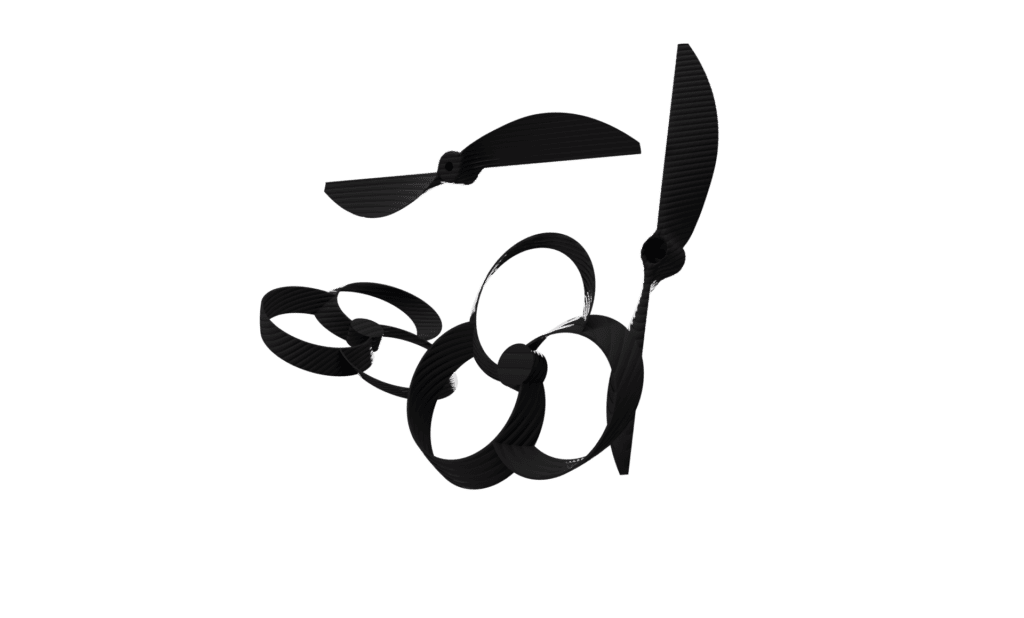

Carbon fiber filled 3D filament is a type of filament used in 3D printing and is reinforced with carbon fiber material. This gives the finished 3D prints improved mechanical properties, including increased strength, stiffness and wear resistance compared to standard filaments. The carbon fiber reinforcement also gives the material a light weight, which is beneficial for manufacturing components where weight reduction is important. The carbon-filled filament is popular in industry and is often used to create high-performance prototypes, tools and final products with advanced technical requirements.

Extruder

200-230 °C

Building plate

45-60 °C

Cooling

100 %

Benefits

Strength and Stiffness

Low Weight

Heat resistant

Disadvantages

Wear on the printhead

Depending on the seller, expensive

Difficulties with Printing

Strength

3d filament comparison

| Feature | Plain Filament | Carbon fiber reinforced filament |

|---|---|---|

| Material composition | Polylactic Acid (PLA) | Polylactic Acid (PLA) with Carbon Fiber Reinforcement |

| Strength | ● ● ○ | ● ● ● |

| Flexibility | Brittle | Generally Less Flexible |

| Printability | ● ● ● | ● ● ○ |

| Surface finish | Standard | Generally Improved |

| Layer stapling | ● ● ○ | ● ● ● |

| Temperature resistance | ● ● ○ | ● ● ● |

| Applications | Basic prototypes, low-load models | Prototypes, functional parts, mechanical components |

*Compared to each other

In conclusion

Thank you for following our comprehensive 3D filament guide, designed to guide both beginners and experienced users towards successful and high-quality 3D printing. From affordable and eco-friendly PLA filaments to robust ABS options and specialized materials such as TPU and carbon-filled filaments, we've covered the full spectrum of possibilities for your unique projects.

Our guide has not only explored the characteristics of each filament type, but also shared tuning tips to optimize your prints. By customizing temperatures, flow rates and overhang settings, you can overcome challenges and create impressive results.

To choose the best filament for your needs and maximize your 3D printing success, we hope our guide has given you the insight and confidence you need. Remember that our goal is to make your journey through the exciting world of 3D printing as smooth and rewarding as possible.

Keep exploring and experimenting to discover new possibilities, and we wish you the best of luck with your future 3D projects. If you have additional questions or need support, our team is here to help. Thank you for choosing us as your guide, and we look forward to following your successful journey in 3D printing!

Don't have the right color for your next project?

We have one of Sweden's and perhaps Europe's widest range of different types with pla filament and more. Choose among other exciting materials, everything from glow in the dark to transparent, and find filaments that suit your next 3D prints.