3d printer guide

Välkommen till vår omfattande guide om 3D skrivare 2024. I denna guide kommer vi att utforska allt från grunderna i 3D utskrift till avancerade tips och tricks för att maximera din 3D utskriftsupplevelse. Oavsett om du är nybörjare eller erfaren användare, har vi samlat all nödvändig information för att hjälpa dig att välja den bästa skrivaren som passar dina behov och budget. Läs vidare för att upptäcka viktiga aspekter att överväga, populära modeller på marknaden, och hur du kan dra nytta av 3D utskrift i dina projekt.

what is a 3d printer?

3D printers are revolutionary devices that create three-dimensional objects from digital files. By adding layers upon layers of material, 3D printers can produce almost any physical object, from prototypes and spare parts to artwork and functional products.

Which 3d printer should you choose?

Choosing the right 3D printer depends on your specific needs, project and budget. For hobbyists or those new to 3D printing, FDM (Fused Deposition Modeling) printers are often the best choice due to their ease of use and relatively low cost. They handle a variety of materials and are excellent for creating everything from simple toys to home projects and prototypes.

If you instead seek a high level of detail for applications such as jewellery, the dental industry or fine mechanical components, SLA (Stereolithography) printers may be more suitable. SLA offers outstanding surface finish and precision but at a higher cost both in purchase and maintenance.

For professional users who need to produce durable and functional parts with complex geometries, SLS (Selective Laser Sintering) can be the right choice. SLS printers are more expensive but ideal for producing high quality parts in small series.

Think about what you want to achieve with your 3D printing before investing in a printer. Consider factors such as material requirements, print size, detail, and budget to find the best 3D printer 2024 that meets your needs.

| Property | FDM | SLA | SLS |

|---|---|---|---|

| Printing process | Extrudes molten plastic through a nozzle. | Cures liquid resin with ultraviolet light. | Uses a laser to melt powder materials. |

| Material | Thermoplastics such as PLA, ABS, PETG. | Photopolymer resin. | Polymer powder, often nylon. |

| Surface finishing | Often rough; visible layers. | Very smooth and detailed. | Smooth, but can be porous. |

| Strength | High in the direction of the layers. | Varies; more brittle than FDM and SLS. | Evenly distributed; generally high. |

| Support structures | Mostly necessary. | Necessary and must be removed after printing. | Not necessary; powder supports the object. |

| Areas of use | Prototypes, hobby projects, simpler functional parts. | Detailed models, molds, jewelry, models. | Complex geometries, functional parts, small series. |

| Cost | Lower. | Medium to high (requires accessories). | Very high. |

| Print speed | Average. | Slower due to the level of detail. | Fast for large batches of objects. |

FDM

Fused Deposition Modeling (FDM) is a 3D printing method where thermoplastic filament is melted and extruded layer by layer to create objects. The method converts digital models into physical ones by printing each layer sequentially, where the molten material solidifies instantly. Known for its simplicity and cost-effectiveness, FDM is popular for making prototypes, educational materials and hobby projects. It supports a range of materials, such as ABS and PLA, making it versatile. FDM is also the most popular 3D Printer of all kinds.

How does FDM technology work?

Here's a step-by-step walkthrough of how FDM works:

Slicer software: This model is then processed by a slicer that creates G-code, which tells the printer exactly how to build the object layer by layer.

Material: The 3D printer uses a thermoplastic filament, such as PLA or ABS, fed into the printer's heated nozzle (extruder). Read more

Printing: The extruder moves over the build plate and lays out the molten material. It solidifies quickly, creating a firm layer. Then the printer builds layer upon layer until the entire object is complete.

Post-processing: The finished object may require cleaning or other finishing to remove the support structure or improve the surface.

Our recommendation in 2024

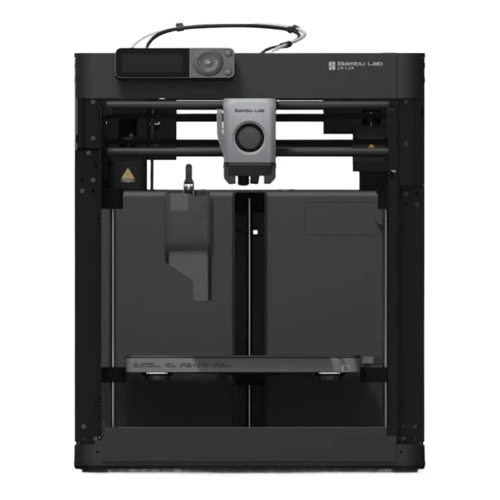

It can be difficult to take the first step out without knowing which printer to buy in 2024. Depending on what your goals are and what you want to do with the printer, the answer may vary. We can warmly recommend the Bambulab P1P as the best 3D printer in 2024 for beginners with a slightly higher budget.

But if you prefer to spend more time and understand the technology behind it, there are still options like a regular Ender 3. The difference here is that you get a 3D printer where almost all the mistakes have already been made, with a community that likely already has the answers you're looking for . Spare parts are also incredibly affordable and readily available thanks to its open-source nature.

Popular 3d printer models

It is an advanced printer that offers high-quality printing and is designed for those who seek precision and speed. It is probably best in class for print quality and speed, but can be a little more complex and expensive than the other models.

A very popular entry-level printer due to its affordable price and ease of use. It has a strong community and lots of online support, making it easy to find guides and troubleshooting help. The quality is good for the price, and it's a strong choice for hobby users and beginners.

This model is intended as a compact and affordable version, suitable for those who have limited space or are interested in printing smaller items. Its size and price make it ideal for beginners or those who want to complement a larger printer.

Popular 3d printer models

It is an advanced printer that offers high-quality printing and is designed for those who seek precision and speed. It is probably best in class for print quality and speed, but can be a little more complex and expensive than the other models.

A very popular entry-level printer due to its affordable price and ease of use. It has a strong community and lots of online support, making it easy to find guides and troubleshooting help. The quality is good for the price, and it's a strong choice for hobby users and beginners.

This model is intended as a compact and affordable version, suitable for those who have limited space or are interested in printing smaller items. Its size and price make it ideal for beginners or those who want to complement a larger printer.

sla

Stereolithography (SLA) is a 3D printing technique where light-sensitive resin (resin) is cured layer by layer with ultraviolet light. This method turns 3D models into physical objects by curing resin in thin layers, causing them to solidify and form the final product. SLA is prized for its ability to produce parts with high detail and smooth surfaces, making it ideal for prototypes, artwork and complex components.

SLA Printer - Things to consider

Material costs

SLA printers use resin, which can be more expensive than the filament used in FDM printers. It is important to budget for material costs.

Post-processing

Objects printed with an SLA printer usually require post-processing, such as washing in isopropanol and post-curing with UV light.

Safety and ventilation

Since SLA printers use chemicals and UV light, it is important to have good ventilation and follow safety regulations.

Popular 3d printer models

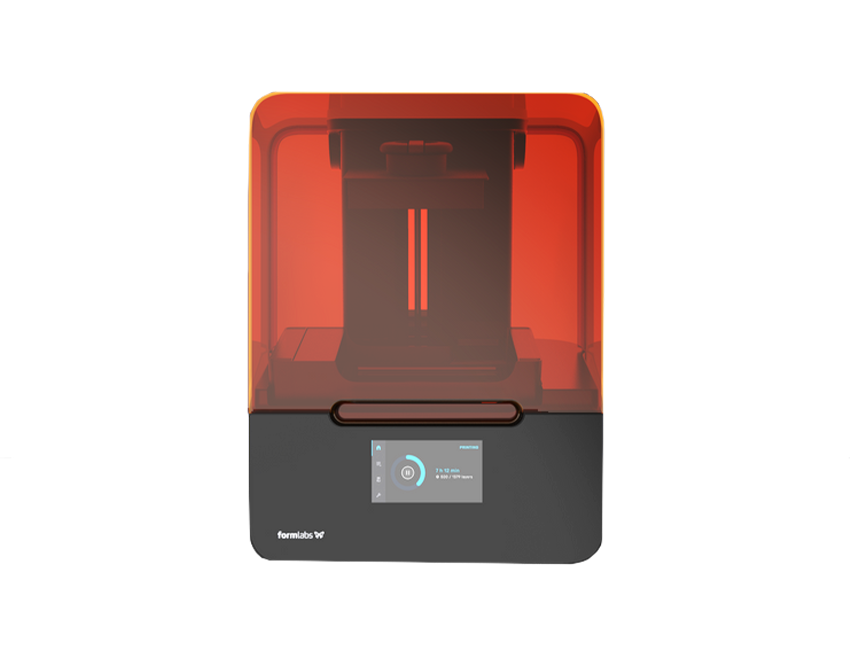

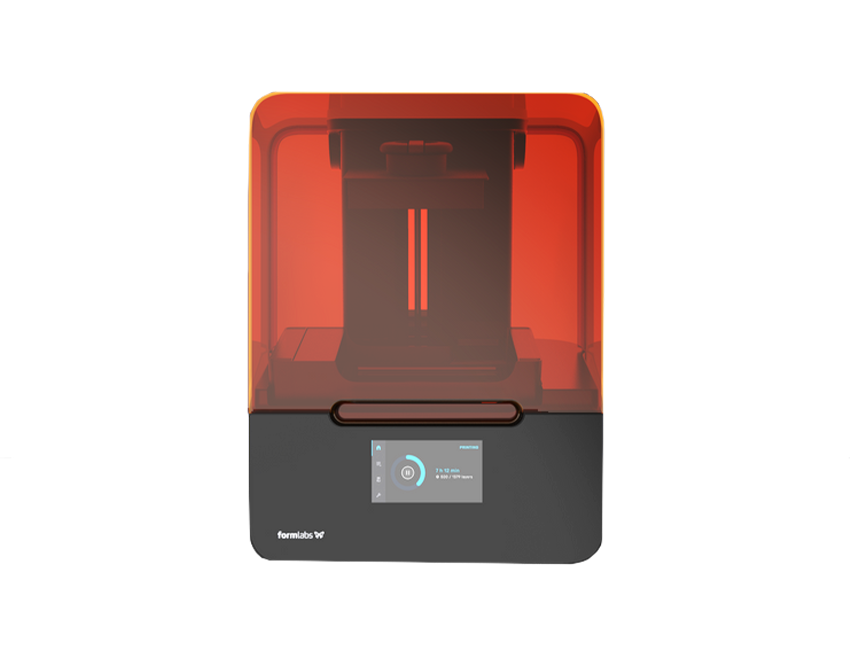

A high performance printer that is well known for its precision and ease of use. Form 3 is suitable for both professional and hobby users who require detailed prints. It has a large user base and extensive aftermarket support, making it easy to find help and resources online.

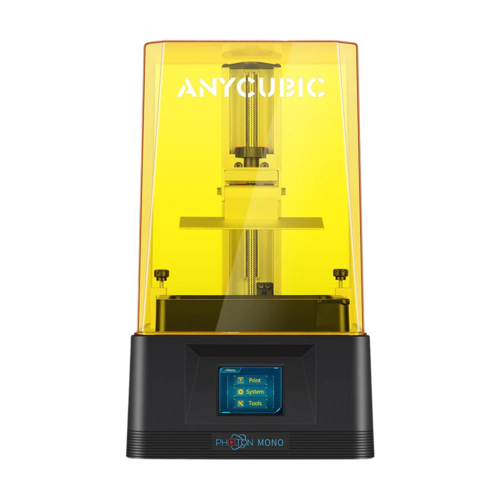

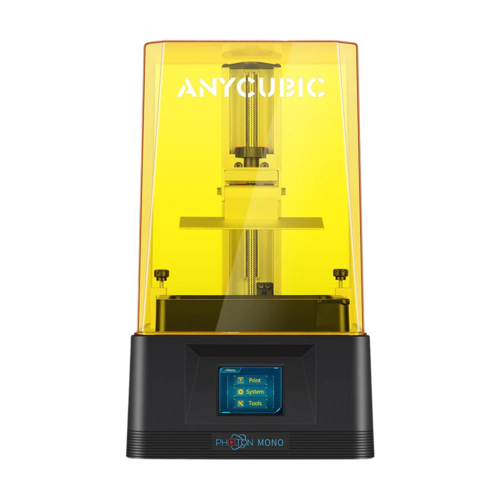

This printer is a favorite among hobby users thanks to its affordability and ease of use. Perfect for small to medium-sized projects, the Anycubic Photon offers an introduction to high-quality resin-based 3D printing without breaking the bank.

An excellent mid-range printer that balances cost and performance. The Elegoo Mars 2 Pro is known for its robust construction and consistent print quality, making it a reliable model for both beginners and experienced users looking for higher precision in their prints.

Popular 3d printer models

A high performance printer that is well known for its precision and ease of use. Form 3 is suitable for both professional and hobby users who require detailed prints. It has a large user base and extensive aftermarket support, making it easy to find help and resources online.

This printer is a favorite among hobby users thanks to its affordability and ease of use. Perfect for small to medium-sized projects, the Anycubic Photon offers an introduction to high-quality resin-based 3D printing without breaking the bank.

An excellent mid-range printer that balances cost and performance. The Elegoo Mars 2 Pro is known for its robust construction and consistent print quality, making it a reliable model for both beginners and experienced users looking for higher precision in their prints.

sls

Selective laser sintering (SLS) is an advanced 3D printing technology that uses a laser to melt and sinter powder materials layer by layer to create solid material. This technology enables the production of parts with complex geometries and high strength, without the need for support structures often required in SLA printing. SLS printers are highly regarded for their ability to create durable and functional parts, making them ideal for engineering applications, functional prototypes and small series final products.

FDM and SLA, When is it time to switch?

If your business is growing, and you encounter limitations with FDM or SLA printing in terms of quality, strength or geometric complexity, it may be time to consider SLS. Although initial investment and operating costs may be higher, the long-term return in terms of quality and efficiency can be well worth the investment.

Increased complexity

Unlike FDM and SLA, SLS does not need support structures. This means that very complex geometries can be printed without the extra work of removing supports, which can save time and materials.

Material diversity

SLS printers can handle a wider range of materials, including high-performance thermoplastics that are ideal for engineering applications.

Professional applications

If your projects require parts that meet stringent industry standards or need mechanical robustness, SLS can provide the quality and reliability you need.

Popular 3d printer models

A high performance printer that is well known for its precision and ease of use. Form 3 is suitable for both professional and hobby users who require detailed prints. It has a large user base and extensive aftermarket support, making it easy to find help and resources online.

This is a compact SLS printer aimed at educational institutions and hobby users. The Sintratec Kit is an affordable introduction to SLS technology, allowing users to experiment with polymer powder sintering efficiently.

Fuse 1 from Formlabs takes SLS technology to a more accessible level and offers a balance between price and performance. It is designed to be user-friendly and requires minimal installation, making it an excellent choice for design studios and small to medium-sized businesses.

Popular models

A high performance printer that is well known for its precision and ease of use. Form 3 is suitable for both professional and hobby users who require detailed prints. It has a large user base and extensive aftermarket support, making it easy to find help and resources online.

This is a compact SLS printer aimed at educational institutions and hobby users. The Sintratec Kit is an affordable introduction to SLS technology, allowing users to experiment with polymer powder sintering efficiently.

Fuse 1 from Formlabs takes SLS technology to a more accessible level and offers a balance between price and performance. It is designed to be user-friendly and requires minimal installation, making it an excellent choice for design studios and small to medium-sized businesses.