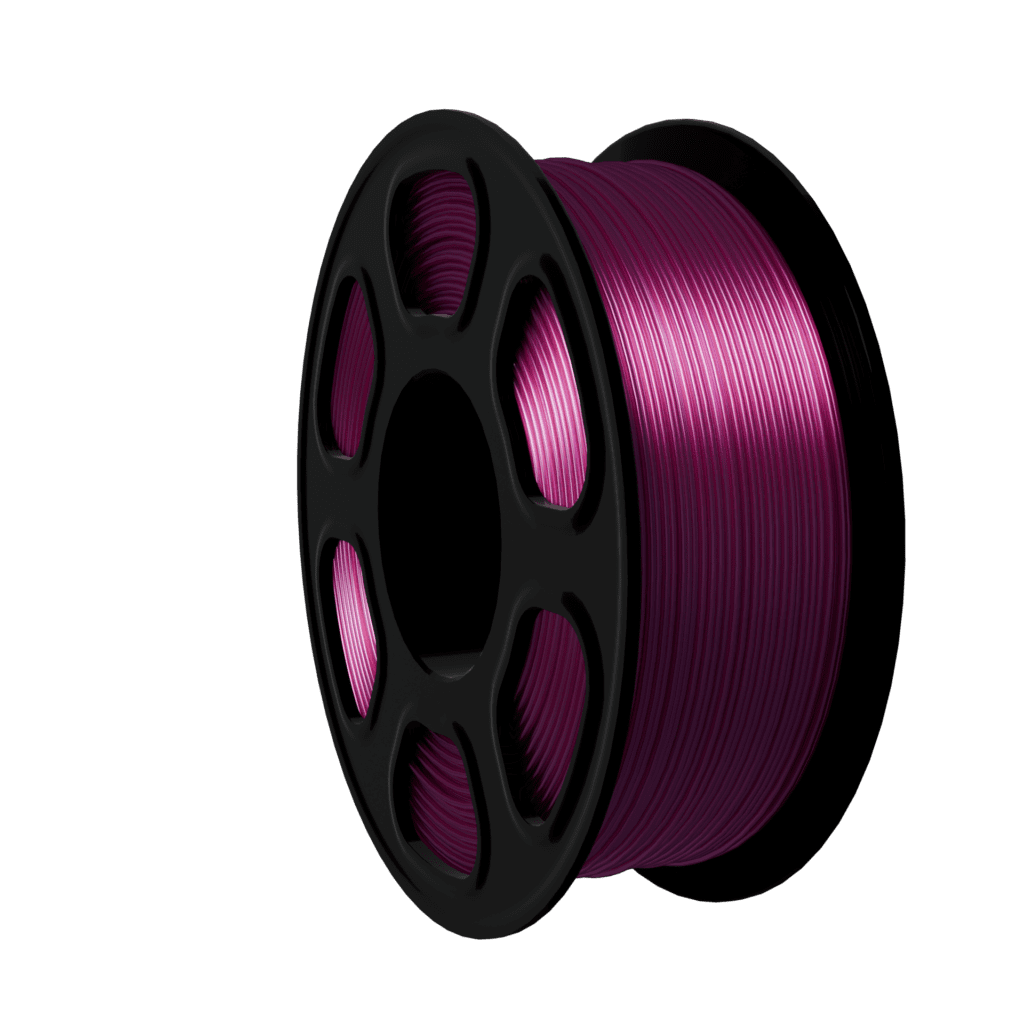

petg filament

What is PETG?

PETG filament, or Polyethylene Terephthalate Glycol, is a popular choice for 3D printing for its special properties and low price. PETG Filament is known for its strength and ease of processing, it is a good choice for projects that place high demands on mechanical and thermal resistance.

Why PETG?

PETG is a popular choice due to its economic and chemical properties. For an overview of other materials, we recommend checking out ours 3D Filament Guide.

Nozzle

230-250 °C

Building plate

75-90 °C

Cooling fan

100%

Benefits

- Inexpensive

- High UV resistance (Good outdoors)

- Chemical Resistance

Disadvantages

- Perceptible For Stringing

- Poor Overhang Ability

- A certain glossy surface

PET + G?

Polyethylene terephthalate glycol-modified (PETG) filament is an advanced co-polyester material designed for 3D printing. PETG Filament combines the robustness and usability of PET with the improved properties of glycol. This creates a filament that is not only ideal for making durable, transparent objects but also overcomes some of the limitations found in traditional PET materials. With glycol modification, PETG reduces the risk of corrosion and crystallization effects, which extends the life of the material and makes it easier to print compared to pure PET materials.

With properties from PET, PETG is naturally a transparent material, this makes it a popular choice when it comes to aesthetically transparent objects and PETG is then usually at the top of the list. The gloss of the material is determined by the printing speed and the temperature of the nozzle.

Common Problems with PETG Filament

Warping:

- Cause: Insufficient adhesion to the print bed can cause PETG components to lift or deform.

- Solution: Use a heated print bed set to the correct temperature for PETG, usually between 75-90°C. A layer of PETG or ABS juice (a mixture of PETG or ABS filaments dissolved in acetone) can help improve adhesion. Also, calibrate first layer height carefully to ensure good first layer adhesion.

Stringing (Threading):

- Cause: Too high a temperature or poor retraction setting can lead to stringing with PETG.

- Solution: Lower the print temperature and adjust the retraction settings. For PETG you may need to experiment with longer retraction length and faster speed compared to PLA to avoid stringing.

Under-Extrusion:

- Cause: Insufficient amount of PETG Filament is extruded, which may be due to a clogged nozzle or incorrect extruder settings.

- Solution: Clean the nozzle to make sure it is not clogged. Check that the filament diameter is set correctly in the slicer software and adjust the flow settings (sometimes in percent) if necessary. Also monitor that the extruder motor does not skip steps.

Layer Separation:

- Cause: Poor adhesion between layers (results in small gaps/gaps)

- Solution: Increase the printing temperature for PETG, which is usually higher than for PLA, to ensure that the layers fuse properly. The right temperature can vary between different brands of PETG, but is often between 230-250°C. A slower print speed can also help the layers bond better.

FAQ

Can I use PETG for outdoor projects?

PETG has excellent UV and weather resistance, making it a good choice for outdoor projects. It holds up better in sunny and humid climates compared to other materials such as PLA. However, for long-term outdoor use, it may be worth considering materials such as ASA instead.

How much cheaper is PETG than PLA?

Today, PETG is often the cheapest material on the market, due to the success and use of PET in everyday life, which has influenced the low prices. The difference can be SEK 20-30. The difference lies in our assortment SEK 15.

Is PETG Waterproof?

PETG filament is essentially waterproof when properly printed and the layers are well fused. This means that objects made with PETG can withstand exposure to water without absorbing it in significant amounts. This makes PETG a suitable material for applications where water resistance is desired. Should it not retain the water, it is usually solved with an additional layer width in the print.